MakeGPT is Live!

World's First AI-powered Hardware Prototype Platform Launched by

Tamil Nadu IT Minister

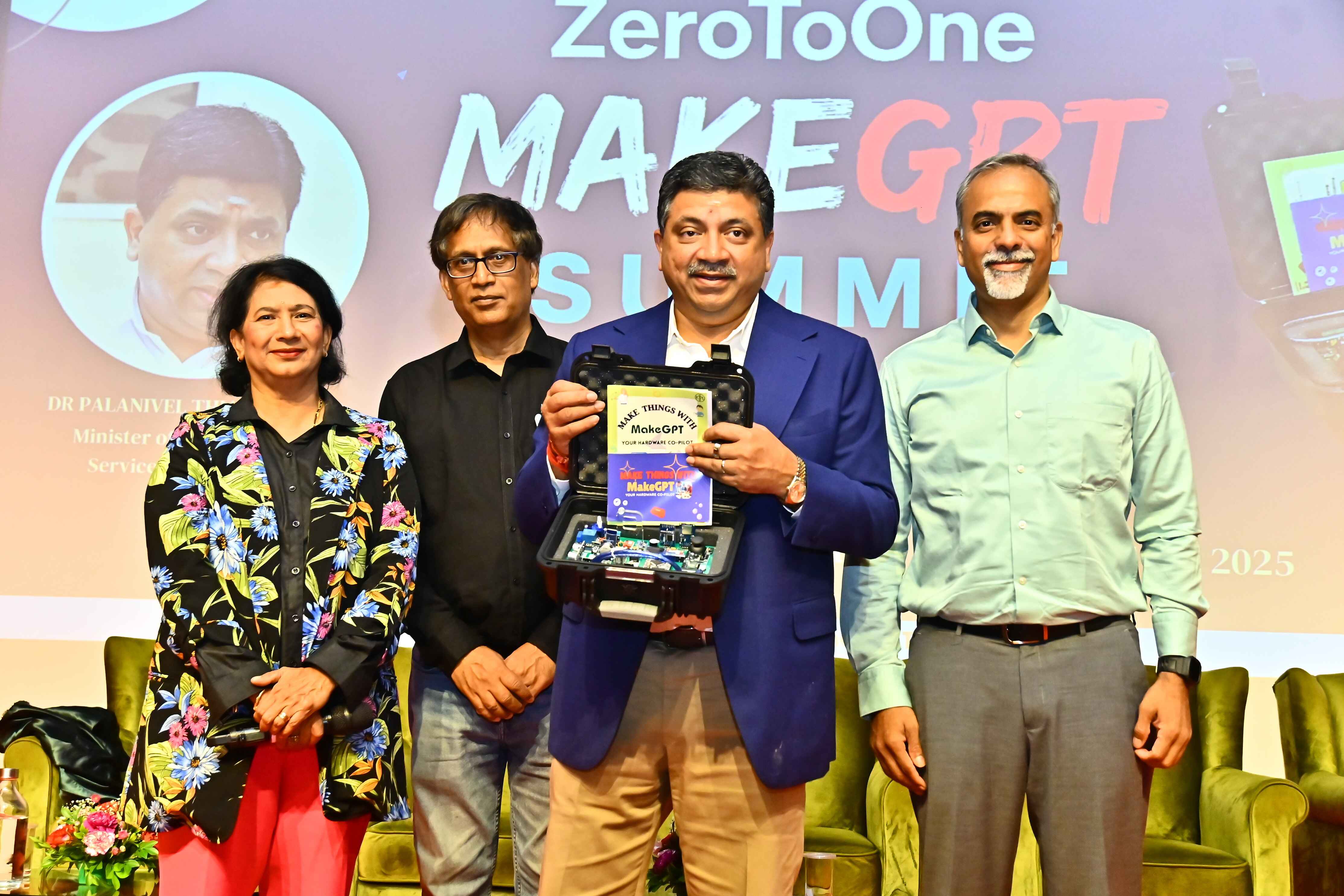

Kochadai Technologies, an IIT Madras incubated startup, has officially launched MakeGPT - a revolutionary AI platform that transforms natural language prompts into IoT prototypes. Our groundbreaking technology was launched by Tamil Nadu IT Minister Dr. Palanivel Thiagarajan at IIT Madras Research Park.

Ready to revolutionize your prototyping process?

Contact Us for Purchase

Event Highlights

Capturing the moments from our revolutionary MakeGPT Summit

Innovation Showcase

The grand Meenakshi Amman Temple — re-created and powered by the MakeGPT team.

Recognition Ceremony

Honouring Madurai’s young innovators for the Meenakshi Amman Temple project.

Kochadai Team

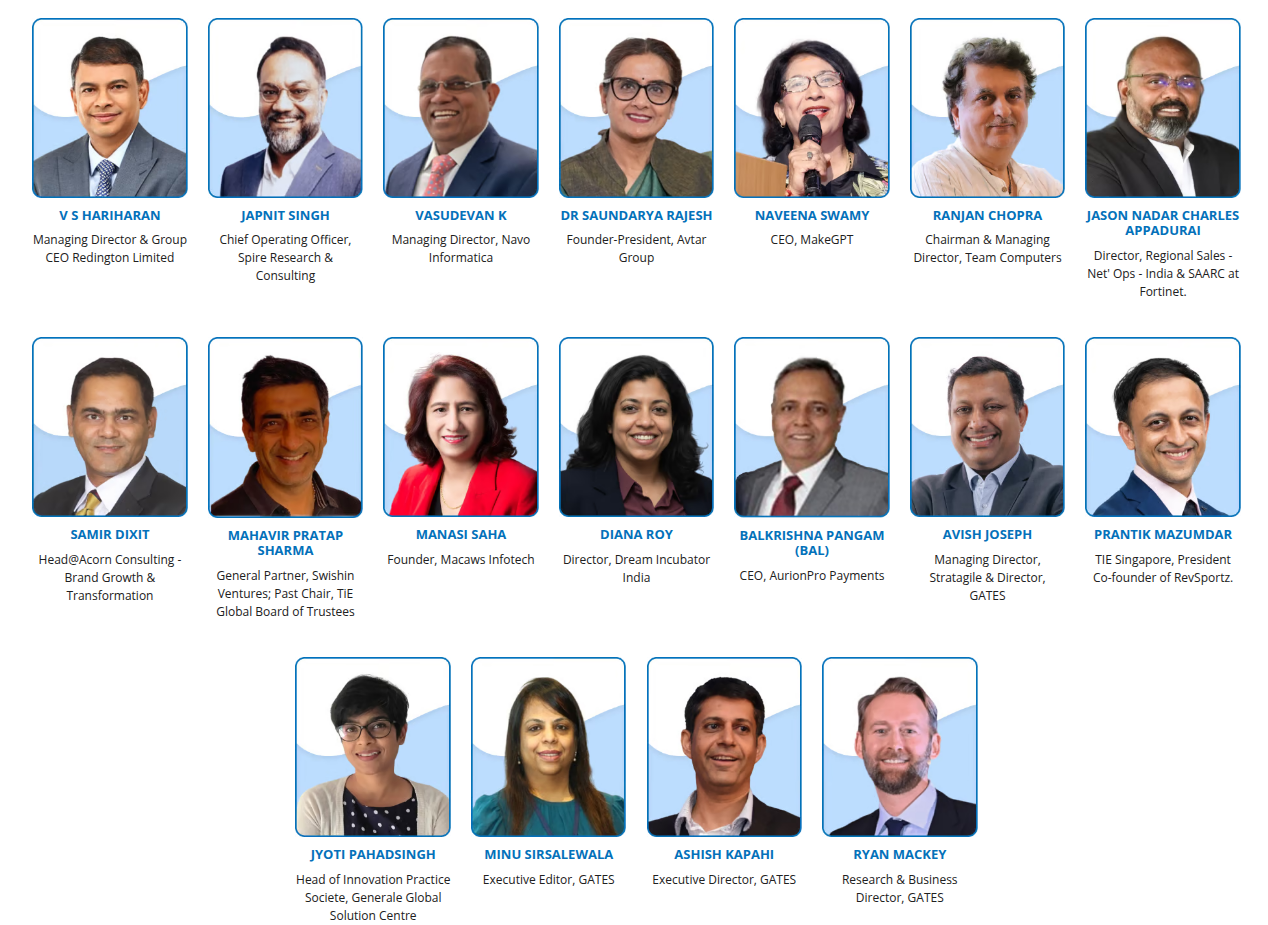

The creative team behind ZerotoOne MakeGPT Summit.

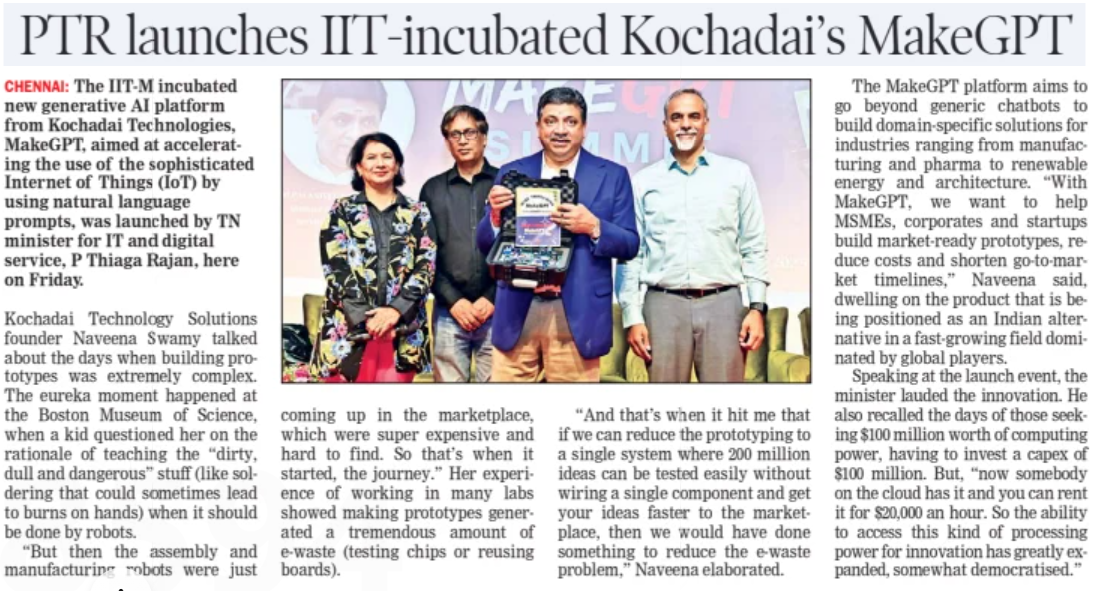

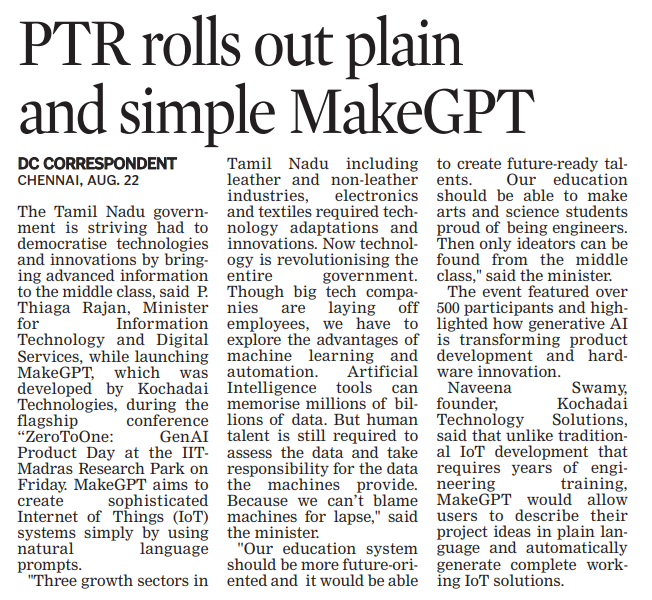

Breaking News Coverage

Major publications worldwide are covering our revolutionary MakeGPT launch

The Hindu

IIT Madras incubated Kochadai Technologies launches MakeGPT to build IoT systems with prompts

Read Article

ETV Bharat

"எதிர்காலமே AI தான்.. மாணவர்களுக்கு கற்றுக்கொடுக்க தொடங்குங்கள்" - பி.டி.ஆர்

Read Article

Digital Terminal

Tamil Nadu IT Minister Dr. P. Thiaga Rajan launches Kochadai's MakeGPT

Read Article

HT Syndication

Kochadai Tech launches MakeGPT, World's First AI-powered Hardware Platform

Read Article🚀 Social Media Buzz

Industry leaders and journalists are talking about our launch